Canada has everything it needs to lead in sustainable bread-making tools: vast forests, world-class pulp producers, and a thriving artisan baking community. Yet one of the most essential tools of sourdough baking—the wood pulp banneton—is almost entirely imported. These baskets, crucial for shaping and fermenting dough, are manufactured overseas and shipped across oceans to Canadian bakeries and homes.

This is an unnecessary gap in Canada’s local food infrastructure. At a time when sustainability, self-reliance, and clean manufacturing are national priorities, it’s hard to justify the absence of a product we are perfectly positioned to produce. This blog post article on The Sourdough People makes the case for manufacturing wood pulp bannetons in Canada—from what they are, to how they’re made, to who could lead the way—and invites the Canadian wood pulp industry to seize this opportunity.

What Are Wood Pulp Banneton Bread Proofing Baskets Used For

Wood pulp bannetons are baskets used during the final fermentation stage of sourdough bread-making. After dough has been mixed, kneaded, and bulk fermented, it’s placed into a banneton to rest and rise one last time before baking. The basket supports the dough’s shape, encourages airflow, and absorbs just enough surface moisture to help form a robust crust.

While bannetons can be made from a variety of materials, wood pulp is the gold standard in many professional bakeries. It’s breathable, lightweight, hygienic, and offers a clean release when the dough is inverted. Its ability to create an ideal fermentation environment makes it more than just a tool—it’s a key ingredient in the sourdough process.

Why Canadian Manufacturing Is Long Overdue

Despite being one of the largest producers of wood pulp in the world, Canada does not manufacture wood pulp bannetons. This results in a paradox: we export the raw materials and import the finished products. Most bannetons used in Canada are manufactured in Europe or Asia, shipped thousands of kilometers, and sold at prices that reflect not just labor and materials—but fuel, packaging, and carbon.

Domestic manufacturing would correct this imbalance. It would also support local artisans and commercial bakeries looking to align their values with their tools. A made-in-Canada banneton would appeal to bakers seeking to minimize their environmental impact while supporting homegrown industry. And for the pulp sector, this product represents a timely and tangible way to diversify into value-added consumer goods.

Types and Sizes of Wood Pulp Bannetons

To make this opportunity practical, Canadian manufacturers need only look to what is already working. Wood pulp bannetons exist in a clearly defined range of forms, each suited to different baking needs. They are not experimental—they’re standardized, proven, and in high demand.

Banneton By Loaf Size (Baked Weight)

Bannetons are sized based on the final baked bread weight, allowing bakers to achieve the perfect dough-to-pan ratio.

500g – Ideal for test bakes, personal loaves, or small boules

750g – The most common size for home bakers and microbakeries

1kg – A commercial workhorse used for full-size artisan loaves

1.25kg to 1.5kg – Suited for enriched doughs or extended fermentation

2kg to 2.5kg – Designed for larger-scale baking and market loaves

Banneton By Shape

Different shapes influence fermentation, crust development, and aesthetic appeal.

Round – Classic boule shape that rises vertically and evenly

Oval – Elongated bâtard shape ideal for slicing

Long Oval – Extended form that offers more surface area and supports higher hydration doughs

Long Angular – Boxier shape used in bakery settings for structured, uniform loaves

Quadratic – Square profile that maximizes oven space and creates bold visual impact

Triangular – Distinctive shape used for visual differentiation and specialty breads

Long Angled – Tapered format that allows for expressive scoring and unique loaf silhouettes

Banneton By Surface Texture

Surface impressions impact the look of the finished loaf and how flour adheres during proofing.

Smooth – Clean finish perfect for scoring and crust development

Spiral – Traditional concentric rings associated with rustic loaves

Creased – Linear grooves that promote flour adhesion and surface character

Waffle – A grid pattern that enhances crust definition

Impressed Motifs – Decorative designs such as suns, hearts, windmills, or celtic symbols for specialty presentation

Banneton By Opening Dimensions

Bannetons are commonly categorized by their top opening dimensions, which align with dough weight and shape. The following are standard and plausible sizes used by artisan and commercial bakers:

Round – 18.4 cm, 21 cm, 22.9 cm, and 24 cm

Oval – 23 x 11.5 cm, 24 x 14.5 cm, 28 x 13 cm, and 30 x 15 cm

Long Angular – 29 x 13 cm, 31 x 13.5 cm, and 33 x 15 cm

Quadratic (Square) – 26 x 15 cm, 25 x 25 cm

Rectangular – 30 x 12 cm, 32 x 14 cm

Triangular – Typically designed for loaves between 750 g and 1.5 kg, dimensions vary but average around 26 cm side length

Specialty Forms – Custom-molded baskets shaped for 500 g to 2.5 kg doughs, often varying in width and wall height depending on design intent

All of these formats are readily available internationally and can be produced locally with the right tools and materials. The demand is already shaped and scaled—Canada simply needs to meet it.

Wood Species in Canada Suitable for Banneton Production

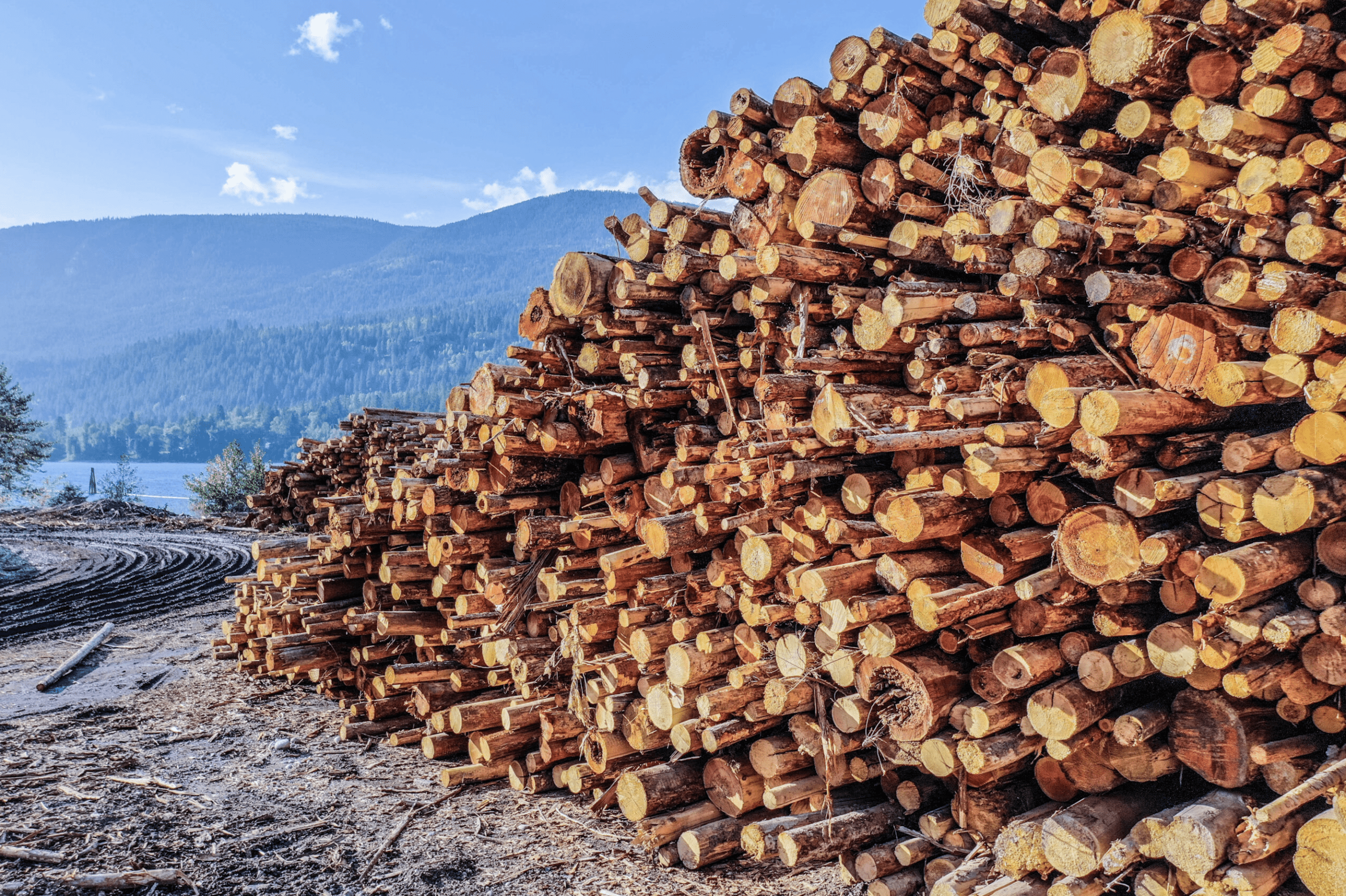

Canada’s forests produce an abundance of softwood species ideal for food-safe molded fiber products. These woods are already used extensively in pulp production and are suitable for adapting into pressed pulp bannetons.

Spruce – Lightweight, long-fibered, and traditionally used in European bannetons

Fir – Durable and dense, offering excellent molding strength

Pine – Highly accessible with a strong fiber matrix

Hemlock – Common in western Canada and frequently used in paper products

The infrastructure to process these woods already exists. With proper tooling and quality controls, these fibers can be turned into high-performance, food-safe proofing baskets using established molding techniques.

Benefits of Domestic Banneton Manufacturing

Manufacturing bannetons in Canada would deliver tangible advantages across sectors, from climate strategy to economic development.

Environmental – Reduced emissions by eliminating long-distance freight, combined with the use of renewable, compostable wood pulp

Economic – Supports regional mills and manufacturers, creates skilled labor jobs, and stimulates pulp-sector growth

Resilience – Strengthens Canadian supply chains, protects against global disruptions, and builds local independence

Cultural – Gives Canadian bakers a tool made from local materials, reflecting shared values of quality, sustainability, and craftsmanship

Tax and Trade – Keeps more revenue in the country and builds a domestic category that can be exported globally

This is a clear example of a small product with large implications—economic, cultural, and ecological.

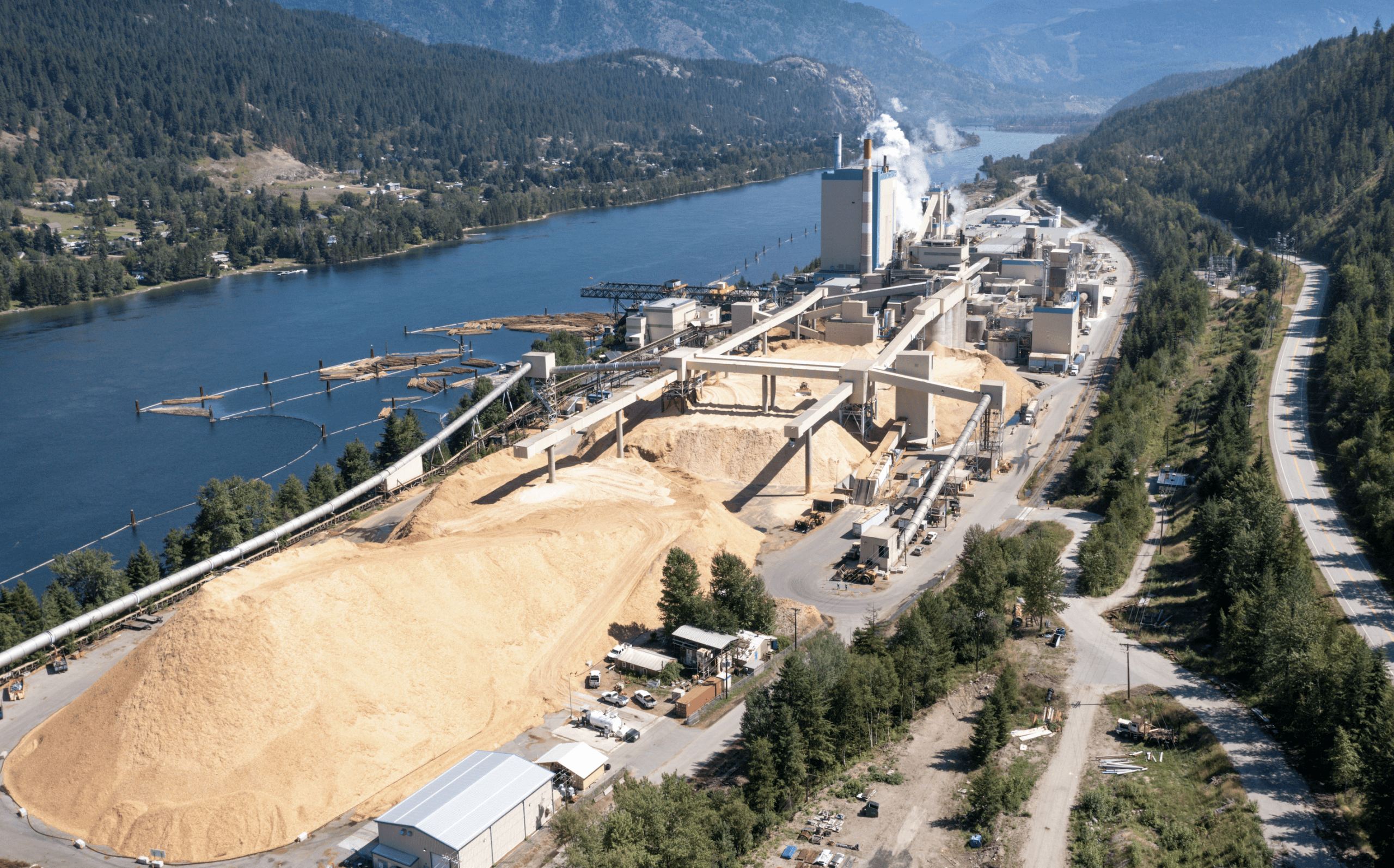

Companies in Canada Positioned to Make Bannetons

Canada is home to a broad network of pulp producers with the infrastructure, materials, and capacity to explore consumer-grade wood pulp products like bannetons. These companies already manufacture high-quality pulp used in everything from paper to packaging, and many are actively seeking new, sustainable product applications.

Potential partners and producers include: Alberta-Pacific Forest Industries Inc. (Al-Pac), Arauco Canada Limited, AV Group NB Inc., Boisaco Inc., Bowater Canadienne Limitée, Canadian Forest Products Ltd., Canfor Corporation (including Canfor Pulp and Cariboo Pulp & Paper), Cascades Inc., Catalyst Paper Corporation, Corner Brook Pulp and Paper Limited, Domtar Corporation, Dryden Fibre Canada, Fortress Specialty Cellulose Inc., GreenFirst Forest Products Inc., Harmac Pacific, Howe Sound Pulp & Paper Limited Partnership, Interfor Corporation, J.D. Irving, Limited (including Irving Pulp & Paper, Irving Paper, and Irving Tissue), Kap Paper, Kruger Inc., Mercer International Inc. (including Mercer Celgar and Mercer Peace River), Millar Western Forest Products Ltd., Neucel Specialty Cellulose Ltd., Nordic Kraft (a subsidiary of Chantiers Chibougamau), Paper Excellence Group (parent of Catalyst, Howe Sound, and Skookumchuck Pulp), Port Hawkesbury Paper LP, Rayonier Advanced Materials Inc. (RYAM), Resolute Forest Products Inc., Stadacona Papers (a division of White Birch Paper), Thunder Bay Pulp and Paper Inc. (owned by Atlas Holdings), Tolko Industries Ltd., Twin Rivers Paper Company Inc., West Fraser Timber Co. Ltd., Western Forest Products Inc., and Weyerhaeuser Company Limited.

With operations spanning multiple provinces, these companies represent a ready-made network of potential collaborators for developing a homegrown supply of Canadian wood pulp bannetons.

Canada’s Wood Pulp Industry by the Numbers

Canada’s wood pulp sector remains a vital component of the national economy, demonstrating resilience and adaptability in a shifting global market. In 2025, the industry is projected to generate approximately $8.5 billion CAD in revenue, marking a modest increase from the previous year.

The core wood pulp manufacturing industry comprises 48 active businesses across Canada, primarily engaged in producing pulp from wood chips and other organic materials. In the broader pulp, paper, and related manufacturing sector, there are over 500 businesses nationwide, spanning packaging, tissue, specialty papers, and molded fiber products.

Employment within dedicated wood pulp mills accounts for approximately 9,404 individuals. However, when considering the broader pulp and paper industry—which includes paper mills, paperboard mills, and converted paper product manufacturing—the workforce expands significantly. As of 2023, the entire sector employed about 57,500 workers, representing 3.2% of Canada’s total manufacturing employment.

Canada’s pulp production is predominantly export-oriented, with approximately 80% of output destined for international markets. The United States and China are primary recipients, accounting for 59% and 22% of exports, respectively.

This extensive infrastructure and global reach underscore Canada’s capacity to diversify into value-added products like food-grade bannetons. Leveraging existing resources and expertise, the industry is well-positioned to meet domestic demand and reduce reliance on imports.

Why This Product Line Fits the Canadian Pulp Sector

The pulp industry in Canada is well established, but like many legacy sectors, it needs to innovate to remain resilient in a changing economy. Wood pulp bannetons offer a rare combination of feasibility, demand, and mission alignment.

Low Cost – Requires minimal raw material per unit and uses existing equipment

High Value – Sells into a specialized, high-margin market with growing demand

Brand Potential – Offers consumer-facing visibility for pulp producers and manufacturers

Diversification – Provides a non-commodity product line that’s aligned with environmental trends

This isn’t about reinventing the wheel—it’s about reapplying known methods to meet a new market need.

A Call to Action for Canada’s Wood Pulp Industry

The Sourdough People is ready to work with pulp producers, bakers, designers, and manufacturers to prototype and produce the first line of Canadian-made wood pulp bannetons. This is not just about bread. It’s about building a supply chain that connects our forests to our food.

We invite you—whether you’re in forestry, manufacturing, bakery operations, or sustainable development—to get in touch. Together, we can create something beautiful, useful, and uniquely Canadian. While positioning locally made banneton sales to Canadians in a direct-to-consumer (D2C) and business-to-business (B2B) wholesale model, through our warehousing and logistics systems.

Closing Thoughts

Canada exports pulp. It grows grain. It bakes world-class bread. But it still imports the very baskets used to shape its loaves.

We can change that. We should change that. Together.

A domestically made wood pulp banneton is more than a product—it’s a statement. About what we can build, about how we support our food culture, and about how we take climate action through the objects we use every day.

The forest is here. The talent is here. The bakers are here. Let’s bring the banneton home.

What Wood Pulp Mills Should Consider

Canada’s pulp industry is globally respected. We have abundant softwood fiber, world-class processing capacity, and an urgent need to move into value-added, sustainable products. Wood pulp bannetons offer a direct, practical path forward.

Here’s what to consider:

The Market Is Ready

Artisan bread-making continues to grow in Canada. Bannetons are essential to this process—but today, nearly all are imported. Bakeries, retailers, and home users are actively looking for a domestic option.

Strategic Alignment with Sector Goals

This product checks all the boxes: renewable materials, low environmental impact, and consumer relevance. It’s a natural extension for mills looking to diversify into sustainable, high-margin goods.

Infrastructure May Already Exist

Mills already producing molded fiber trays or food-grade containers are likely partway there. The process—pressing pulp into shaped molds using heat and pressure—is familiar and often adaptable.

Tooling and Technical Readiness

This is where production becomes product. Bannetons require:

Precision molds to create distinct shapes and textures (spirals, smooth, creased)

Heat-press forming lines capable of holding tolerances and drying without warping

Food-safe release agents (if used) and non-contaminating surfaces

Pilot tooling for iterative prototyping, especially when introducing size variations

Custom aluminum or epoxy molds can be made in Canada, and design partnerships with bakeries can ensure real-world performance before scaling.

Ideal Use of Canadian Fiber

Long-fiber species like spruce, fir, and pine—abundant in Canada—are ideal for strong, breathable baskets. Properly refined, they provide durability, dough release, and structure comparable to European imports.

Compliance with Food-Contact Standards

Clean production lines, traceable sourcing, and CFIA compliance are required. Most mills producing food-safe pulp packaging already meet or can easily reach these benchmarks.

Uniformity and Quality Assurance

Proofing baskets must be consistent in shape, wall thickness, and surface pattern. Variability affects bread quality. This makes quality control and mold repeatability essential—especially in retail or wholesale volumes.

Branding, Packaging, and Market Positioning

This is a story product. Canadian-made bannetons offer a powerful sustainability and origin narrative. Presentation, instructions, and thoughtful design create value beyond the form itself.

Strong Competitive Advantage

Producing locally cuts freight emissions, reduces delays, and keeps revenue in the Canadian economy. It offers a rare mix of low-input cost and high perceived value—ideal for modern manufacturing portfolios.

The technical path is real, the market is ready, and the product fits the moment. For Canadian pulp mills, bannetons aren’t a leap—they’re a logical next step.

Why This Matters to Canadians

Canada produces the grain, grows the trees, and bakes the bread—but still imports the baskets used to shape its loaves. Producing wood pulp bannetons here at home isn’t just about economics. It’s about aligning industry with Canadian values, strengthening self-reliance, and investing in our own food systems.

Strengthens Local Economies

Domestic manufacturing supports regional mills, small towns, and the forestry workforce. It keeps value within the country—from raw material to finished product.

Creates Skilled Canadian Jobs

Each banneton sold supports more than just pulp production. It generates work in mold-making, design, marketing, packaging, logistics, and retail.

Connects Forestry to Food Culture

Making bannetons from Canadian wood pulp builds a visible, tactile connection between forest products and Canada’s growing artisan baking scene. It closes the loop between land, material, and food.

Promotes Canadian Identity

A well-crafted banneton can carry a “Made in Canada” label with pride. It becomes a symbol of national quality, self-sufficiency, and sustainable design.

Respects Bilingual and Multicultural Realities

Canadian-made bannetons can be labeled in both French and English, and designed to reflect global and Indigenous baking traditions. This creates a product line that’s culturally inclusive by default.

Supports Food System Resilience

Local manufacturing means fewer disruptions from global supply chain issues. Canadian bakeries, retailers, and consumers benefit from faster turnaround and more reliable access.

Reduces Carbon Emissions

Importing heavy goods from overseas adds unnecessary emissions. Canadian production eliminates ocean freight and significantly lowers transport distances.

Keeps More of the Story at Home

From trees to tools to tables, producing bannetons in Canada allows us to tell a fully Canadian story—one that integrates sustainability, craft, and community.

Aligns with National Priorities

Governments and industries alike are prioritizing domestic manufacturing, renewable materials, and circular economies. Bannetons deliver on all three.

Sends a Message About Values

Choosing to make everyday tools locally—even small ones—signals something bigger: that we value transparency, stewardship, and the power of thoughtful design.

Bringing banneton production to Canada isn’t just practical—it’s meaningful. It’s a chance to shape not just our bread, but the kind of economy and culture we want to grow.

Environmental Benefits to Canada

Producing wood pulp bannetons in Canada delivers real environmental value—cutting waste, reducing greenhouse gas emissions, and supporting national sustainability goals through practical, localized action.

Reduces Transportation-Related Greenhouse Gas Emissions

Imported bannetons often travel thousands of kilometers by ship, rail, and truck. Domestic production eliminates this long-haul freight, reducing greenhouse gas emissions tied to international transport.

Relies on Renewable, Responsibly Managed Canadian Fiber

Softwoods like spruce, pine, and fir are sustainably harvested under Canadian forestry standards. They’re fast-growing, renewable, and well-suited to clean, natural fiber molding.

Decreases Packaging Waste

Products built for international shipping require additional packaging and handling. Local manufacturing reduces this need—cutting down on material use, waste, and energy.

Replaces Plastic and Synthetics with Compostable Materials

Wood pulp bannetons are fully biodegradable. They contain no plastics, coatings, or fossil-derived components—leaving behind no landfill waste or microplastics at end-of-life.

Supports Low-Impact Mill Operations

Molded fiber production can be done using closed-loop water systems and low-chemical processing. Waste pulp can often be reused internally, minimizing industrial impact.

Improves Canadian Circularity

Turning domestic fiber into durable, reusable goods keeps both materials and value within Canada. It supports a shift from resource extraction to circular production and reuse.

Reinforces National Climate and Industrial Policy

Greenhouse gas reduction, clean manufacturing, and local value chains are all national and provincial priorities. Banneton production offers a small but visible way to put these policies into practice.

Localizing this product does more than cut imports—it cuts emissions, reinforces circularity, and helps Canada demonstrate environmental leadership through everyday tools.

Bannetons Around the World

Though often called bannetons in Canada and France, bread proofing baskets have taken many names and forms around the world. Across centuries and continents, cultures have developed their own versions of these essential tools—each designed to gently support dough during fermentation, encourage airflow, and shape a loaf’s final form.

Today, Canada has the chance to not just manufacture bannetons, but to reflect this global heritage through inclusive, thoughtful design.

France – Banneton

The term banneton originates from the French baking tradition and remains widely used across French-speaking regions and global artisan circles. Typically made from willow, rattan, or wood pulp, bannetons are prized for their breathability and ability to wick excess moisture—producing a crisp, well-structured crust. French boulangers often dust them with rye flour and rely on them for shaping bâtards, boules, and pain de campagne.

Germany – Brotform / Gärkorb

In German-speaking countries, proofing baskets are called Brotform (bread form) or Gärkorb (fermentation basket). These forms are often deeper than their French counterparts and emphasize structure for dense rye or wholegrain loaves. The traditional spiral impression—common on rustic sourdough—traces back to these designs. They’ve long been used in communal village bakeries and are now standard in both home and commercial setups.

Italy – Cestino di Lievitazione / Paniera

Italian bakers use cestino di lievitazione (leavening basket) or paniera to refer to proofing vessels. These may be lined or unlined, and are common in shaping regional breads like pane toscano, ciabatta, and pane casereccio. Italian forms prioritize gentleness and are sometimes crafted from woven reeds or cloth-lined terracotta.

Middle East & North Africa – Fermentation Bowls & Dough Cradles

In Arabic-speaking regions and North Africa, traditional breads like khubz, barbari, and msemen are proofed in shallow wooden bowls, floured trays, or between layers of cloth. While not always circular or basket-like, these vessels serve the same purpose: to cradle the dough during its final rise, preserve its moisture, and prepare it for high-heat baking surfaces like taboons or tandoors.

East & Southeast Asia – Bamboo Steaming Baskets & Proofing Trays

Though sourdough is not traditional, many East Asian cuisines use natural fiber baskets for resting and fermenting doughs. Bamboo steaming baskets, used for buns like bao or mantou, allow for gentle humidity control. Rice flour or wheat-based doughs are often shaped and rested in shallow, breathable trays. The principles—support, breathability, and surface preservation—are the same.

Africa & South Asia – Cloth Proofing, Woven Trays, and Banetons-in-Use

In Ethiopia, injera batter is rested in covered clay or fiber vessels. In India and Pakistan, enriched doughs like naan or kulcha are sometimes rested in large bowls or covered cloth nests. Increasingly, formal bannetons are adopted into professional bakeries worldwide, even in places where traditional methods never used baskets.

North America – Banneton / Proofing Basket

In Canada and the U.S., both banneton and proofing basket are common terms. These are used widely in microbakeries, culinary schools, and home kitchens. Most are imported, yet Canadian bakers are increasingly seeking well-made, locally produced options—reflecting values around sustainability, food sovereignty, and cultural awareness.

Shared Function, Distinct Identity

Despite variations in name, material, and form, the purpose of these vessels remains consistent: to provide structure during fermentation, regulate surface moisture, and leave a signature on the final loaf—whether it's a spiral ring, a soft edge, or a distinctive score.

A Canadian Opportunity for Inclusive Design

By producing bannetons domestically, Canadian manufacturers can reflect these traditions through variety in shape, size, surface texture, and labeling. This includes offering bilingual or multilingual packaging, honoring Indigenous grain stories, and providing educational materials that speak to cultural diversity in bread-making.

Proofing baskets have always told stories—about place, grain, method, and identity. A banneton made in Canada can do the same: rooted in history, open to all, and ready for what’s next.

Design Customization Opportunities

Producing bannetons in Canada isn’t just about supply—it’s about creative control. Local manufacturing gives Canadian companies the ability to shape how bannetons look, feel, function, and resonate culturally. This opens the door to meaningful design, inclusive storytelling, and global market differentiation.

Tailored Sizes and Forms

Domestic production allows for precise molds in various shapes—round, oval, square, long angular, and more. Sizes can align with standard loaf weights from 500 g to 2.5 kg, giving bakers better control and consistency.

Performance-Driven Surface Textures

Spiral grooves, smooth interiors, crosshatch textures, or linear creases influence fermentation, flour adhesion, and crust development. These textures are not decorative—they shape the final loaf.

Embossing and Branding Potential

Molds can be customized with logos, motifs, or visual patterns. This allows for bakery branding, retailer exclusives, or themed production runs tied to culture, seasonality, or geography.

Multilingual and Inclusive Packaging

Bilingual labeling in English and French is a baseline, but manufacturers can go further—creating packaging and care materials that include other languages and visual instructions, making bannetons accessible to more Canadians.

Culturally Responsive Design Options

Form factor, motifs, and marketing can reflect Indigenous, regional, or global bread-making traditions. Whether honoring local grains or heritage loaves, Canadian bannetons can be intentionally inclusive.

Flexible Production and Prototyping

Canadian mills and design shops can support short production runs for culinary schools, microbakeries, or new product lines—lowering the barrier to innovation and collaboration.

Certifications and Traceability

Canadian bannetons can carry clear labeling around compostability, CFIA compliance, and forest source. This builds trust and aligns with buyer expectations in both retail and export markets.

Retail-Ready Experience

With thoughtful packaging, reusable cloth wraps, or branded sleeves, bannetons become more than tools—they become gifts, professional-grade products, and storytelling vehicles.

Canadian manufacturers aren’t just positioned to meet demand—they’re positioned to lead. Through smart design and thoughtful customization, bannetons made here can become the most compelling in the world.

Connecting With Sourdough Bakers

Sourdough bakers are more than end users—they’re community builders, product testers, and brand amplifiers. For Canadian pulp mills and manufacturers, building relationships with this group creates a direct, credible path to market validation, early adoption, and long-term visibility.

Aligned Values, Aligned Priorities

Sourdough baking is rooted in tradition, patience, and sustainability. Bakers care deeply about their tools—seeking products that are renewable, local, and thoughtfully made. A Canadian banneton built from domestic fiber speaks directly to those values.

Small Orders, Large Influence

Most bakers start with a few baskets—but their impact is wide. Through markets, workshops, and social media, they introduce new products into trusted networks. One good banneton can lead to dozens of referrals.

Practical Insights From Daily Use

Sourdough bakers are detail-focused. They notice mold depth, dough release, surface texture, and crust behavior. Inviting their feedback helps refine the product early and ensures it performs under real-world bakery conditions.

Tools That Educate and Inspire

Pairing a banneton with bilingual care instructions, fermentation tips, or origin information elevates the product experience. These extras matter, especially for home bakers and educators.

Trust Is Built Through Access and Responsiveness

Offering sample runs, responding to feedback, and involving bakers in product evolution builds loyalty and creates a two-way relationship. This also helps identify niche needs before scaling.

A Direct Link Between Material and Culture

Pulp producers work with fiber. Bakers work with fermentation. Bringing these disciplines together creates tools that connect material science to everyday craft—and makes the final product more meaningful.

Shared Storytelling, Local First

When a baker can say, “This was made by a pulp mill in Canada,” it adds authenticity to every loaf. That connection becomes part of the customer experience—and the product’s reputation.

Connecting with sourdough bakers is not just smart outreach—it’s strategic design collaboration, grassroots marketing, and cultural alignment all in one.

Useful Resource Links

Wikipedia Overview

The Canadian Encyclopedia

Statista Datasets

Pulp and Paper Canada

Government of Canada

Dun & Bradstreet

PAPTAC Organization